What contribution will ASI & Narrow AI make in Gold mining

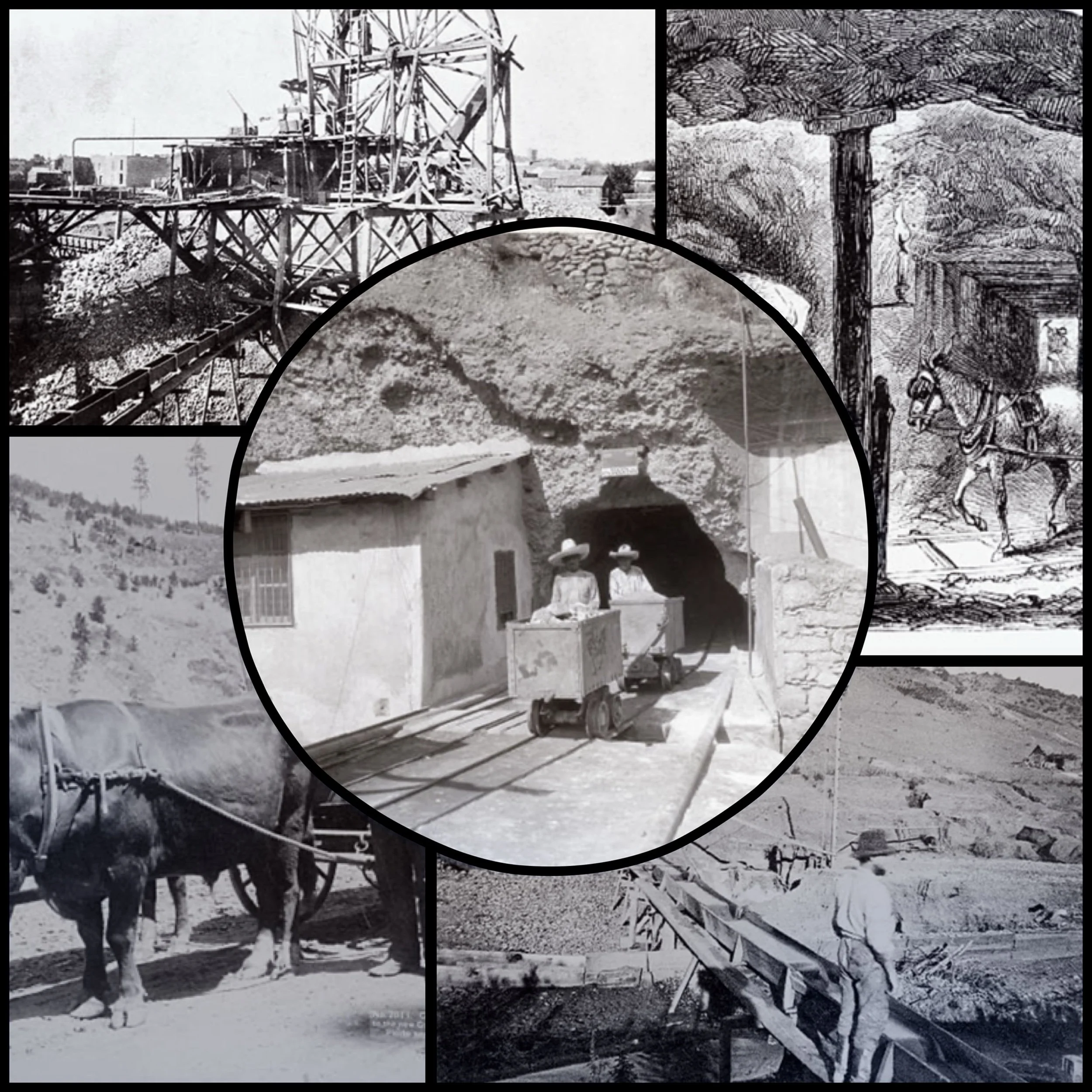

Introduction

Norrow mining is expected to contribute significantly to the gold mining industry through its autonomous solutions. General & ASI contribution are more hypothetical but will involve within time with research and results.

Let’s review key contributions

Autonomous Operations

OEM agnostic autonomous solutions, allowing for the automation of mixed fleets of mining vehicles regardless of brand. This has been demonstrated in projects like the deployment of autonomous haul truck conversions for Komatsu 930E-2 trucks at Nevada Gold Mines, enhancing operational efficiency and safety

Safety Improvement

By removing humans from hazardous areas, such as blast benches, the solutions improve mine safety. This is particularly beneficial in gold mining where operations can be dangerous due to the nature of underground or open pit mining.

Productivity and Efficiency

The implementation of autonomous technology can lead to greater utilization of equipment, reducing downtime and improving productivity. This is crucial in gold mining where margins can be tight, and operational efficiency directly impacts profitability.

Cost Reduction

While not directly lowering the all-in sustaining costs (AISC) per ounce of gold, automation can lead to reduced operational costs through better fleet management and reduced labor requirements in the long term. This can help in managing or potentially lowering the rising costs noted in the industry

The economic benefits of using AI in gold mining are substantial and wide-ranging, impacting various aspects of the mining process:

Exploration and Resource Estimation

AI-powered exploration techniques can predict 86% of gold resources using only 4% of the total surface area data, dramatically improving exploration targeting and efficiency.

Machine learning algorithms analyze vast amounts of geological data, reducing exploration costs and increasing the accuracy of resource estimation.

Operational Optimization

Productivity Improvements

Some mining companies have improved their mining throughput by 10-20% through AI implementation.

AI-driven autonomous vehicles and machinery optimize routes and execute tasks with precision, enhancing overall operational efficiency.

Cost Reduction

McKinsey estimates AI will be worth up to US$290-US$390 billion in annual savings for producers of various minerals, including gold, by 2035.

Predictive maintenance systems minimize equipment downtime and repair costs.

Process Optimization

AI analyzes data from various stages of the mining process to optimize resource extraction, reduce waste, and improve overall efficiency.

Real-time monitoring and analysis of production processes enhance efficiency across the entire mining value chain.

Supply Chain Management

AI optimizes logistics operations, including transportation routes and distribution networks.

Predictive inventory management leverages AI to reduce inventory planning time and minimize costs.

Safety Improvements

By automating hazardous tasks, AI-powered systems reduce worker exposure to dangerous conditions, potentially lowering insurance and healthcare costs.

Environmental Impact

AI-driven systems monitor and manage environmental impacts, potentially reducing costs associated with environmental compliance and remediation.

Investment Attraction

The implementation of AI technologies can make mining projects more attractive to investors by reducing the “back-ended risk premium,” potentially lowering the cost of capital for mining companies.

AI is transforming the economics of gold mining by improving efficiency, reducing costs, enhancing safety, and optimizing processes across the entire value chain. As AI technologies continue to evolve, they promise to unlock even more economic potential in the gold mining industry.

Role of Artificial super intelligence in mining - a leap forward

As of January 2025, there is no concrete information or evidence regarding the contributions of Artificial Super Intelligence (ASI) to gold mining. ASI, which refers to AI systems that surpass human intelligence across all domains, remains a theoretical concept and has not been developed or implemented in any industry, including gold mining.

Current information focus is on narrow AI and machine learning applications in the mining sector, which are already making significant impacts. These include:

Enhanced exploration and resource estimation using machine learning algorithms to analyze geological data and identify potential gold deposits more accurately.

Operational optimization through predictive maintenance, autonomous machinery, and real-time process adjustments.

Improved safety measures using AI-powered risk assessment and monitoring systems.

More efficient decision-making processes based on complex data analysis and predictive modeling.

Environmental monitoring and sustainability improvements through AI-driven resource management and impact assessment.

While these advancements are significant, they fall under the category of narrow AI rather than ASI. The mining industry, including gold mining, continues to benefit from and invest in these AI technologies, but ASI remains a concept for the future with no current applications or specific expectations in the field.

Conclusion

These contributions are expected to not only enhance the operational aspects of gold mining but also support the industry's move towards more sustainable and efficient mining practices.